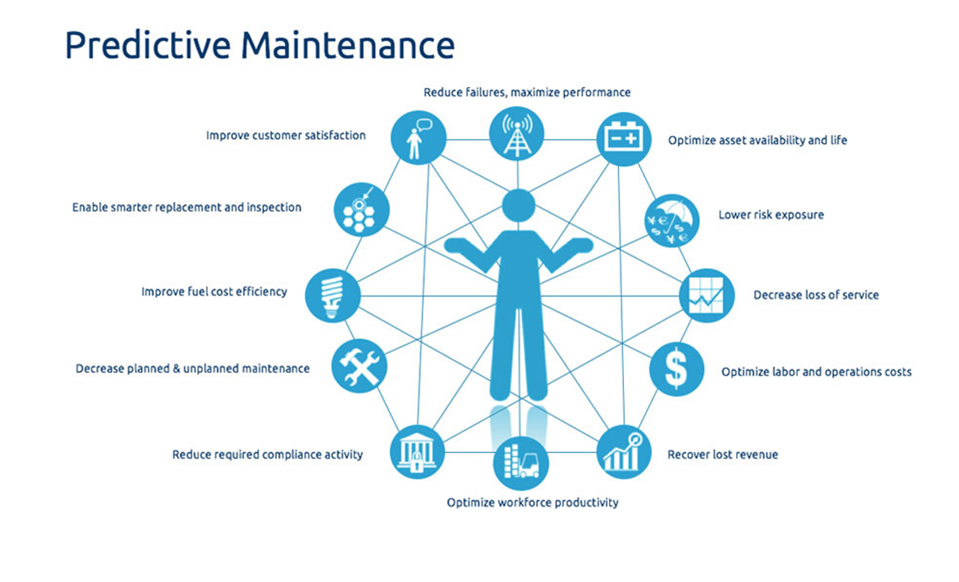

Predictive Maintenance

What is predictive maintenance?

Predictive maintenance is a strategy used in industry to predict when a failure is likely to occur in an equipment or system, so that preventive measures can be taken before the failure occurs. It is based on the collection of data and its analysis to identify patterns or trends that may indicate imminent deterioration or malfunction.

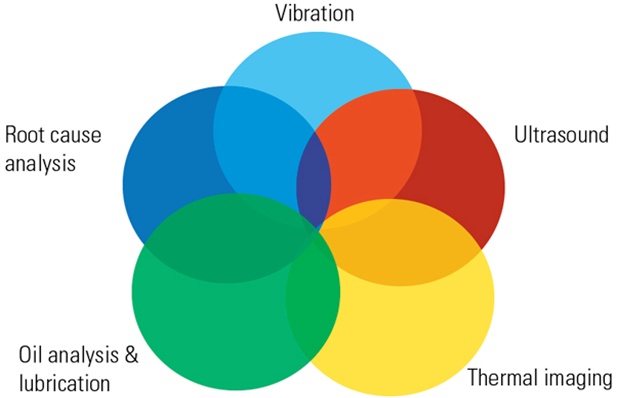

This approach involves the use of various monitoring and analysis techniques, such as vibration analysis, thermography, oil analysis, ultrasound, visual inspection, among others, depending on the type of equipment and operating conditions. These techniques make it possible to detect early signs of problems and carry out planned interventions, such as repairs or preventive maintenance, rather than waiting for an unexpected failure to occur, which can be costly in terms of downtime and emergency repairs.

What are Predictive Maintenance Technologies applied to?

Plant Machinery:

Pumps

Compressors

Fan

Blowers

Agitators

Generators

Conveyors

Electrical Components:

MCCs

Transformers

Local disconnects

Power panel

MG Sets

Circuit Breakers

Capacitors Banks

Services

Predictive Maintenance Services

Vibration Analysis

Vibration Analysis allows to diagnose mechanical failures before they turn catastrophic, such as bad bearings, gear wear, misalignment, umbalances, etc.

Read MoreOil Analysis

Oil Analysis identifies poor lubricant condition or machine wear to aid to the predictive maintenance diagnosis.

Read MoreInfrared Thermography

Identifies poor electrical connections, poor insulation, electrical component issues and others to avoid downtimes.

Read MoreLaser Alignment

The latest laser technology is applied to properly align machines and avoid high vibrations or energy inefficiencies.

Read MoreDynamic Balancing

Vibration instruments help to balance any rotor to minimize vibration and wear, extending life of components and machines.

Read MoreSound and Noise Evaluations

This assessment involves measuring noise levels in different areas of the industrial facility. The data collected helps identify the primary sources and noise levels.

Read MoreClients